OUR PRODUCTS

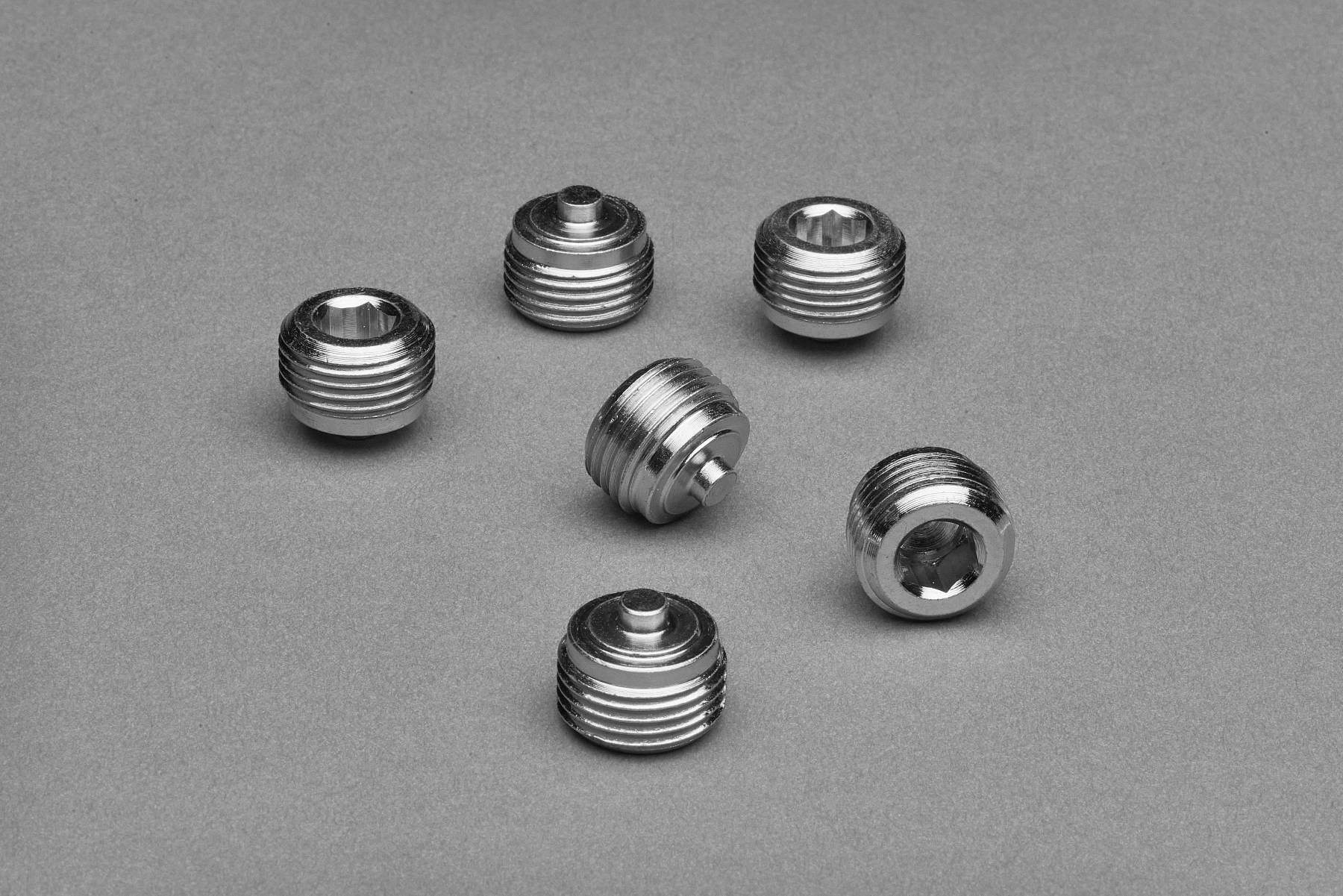

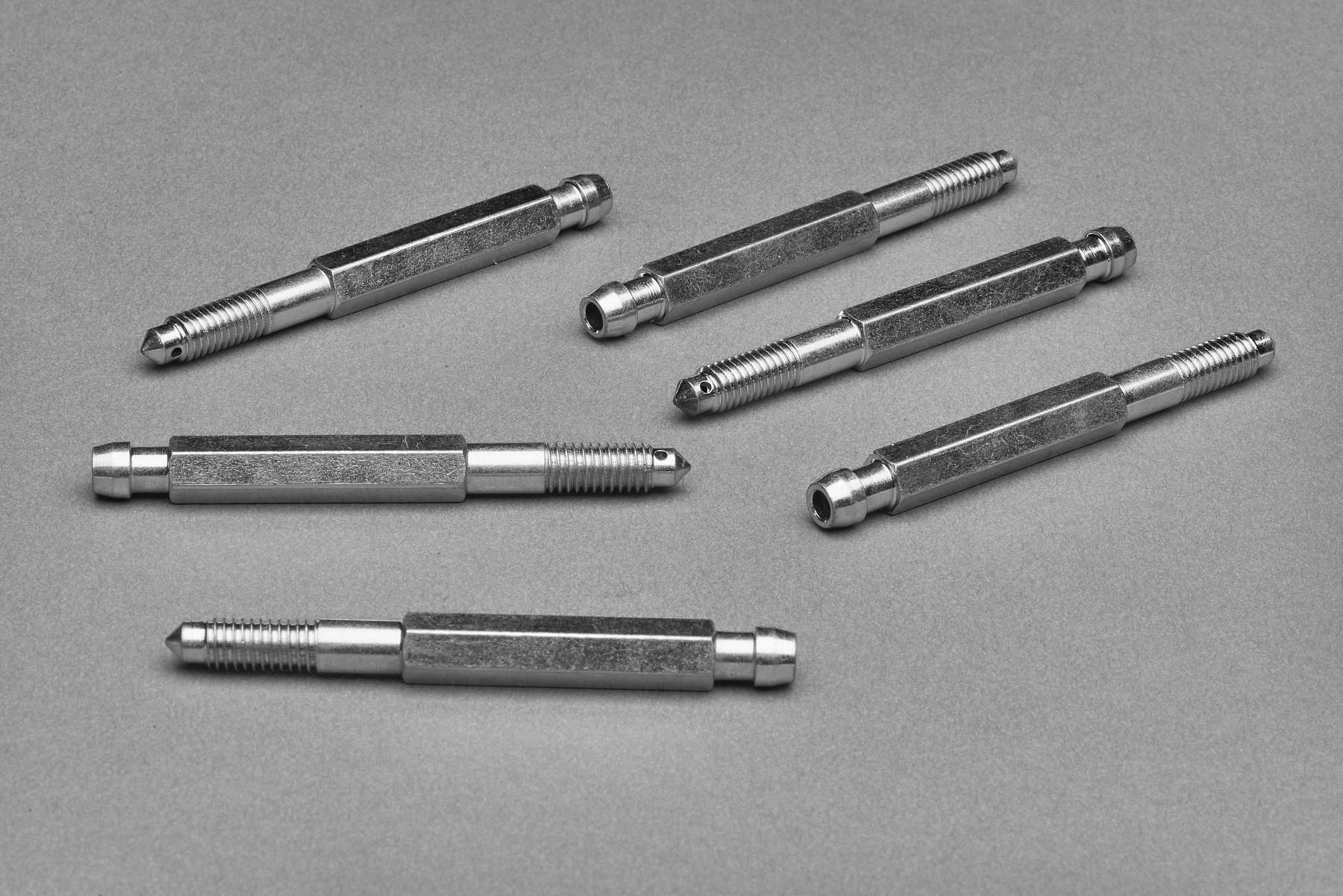

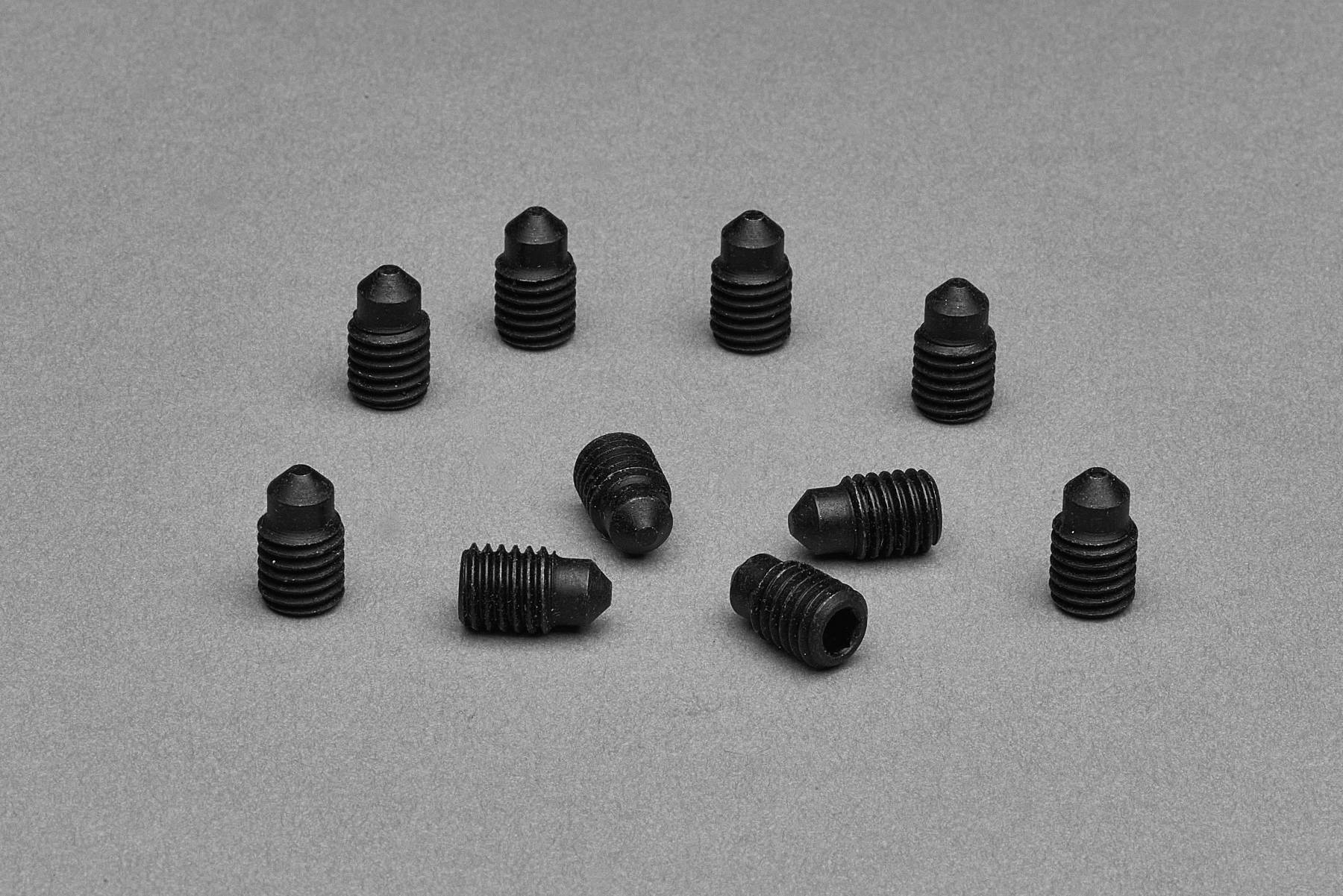

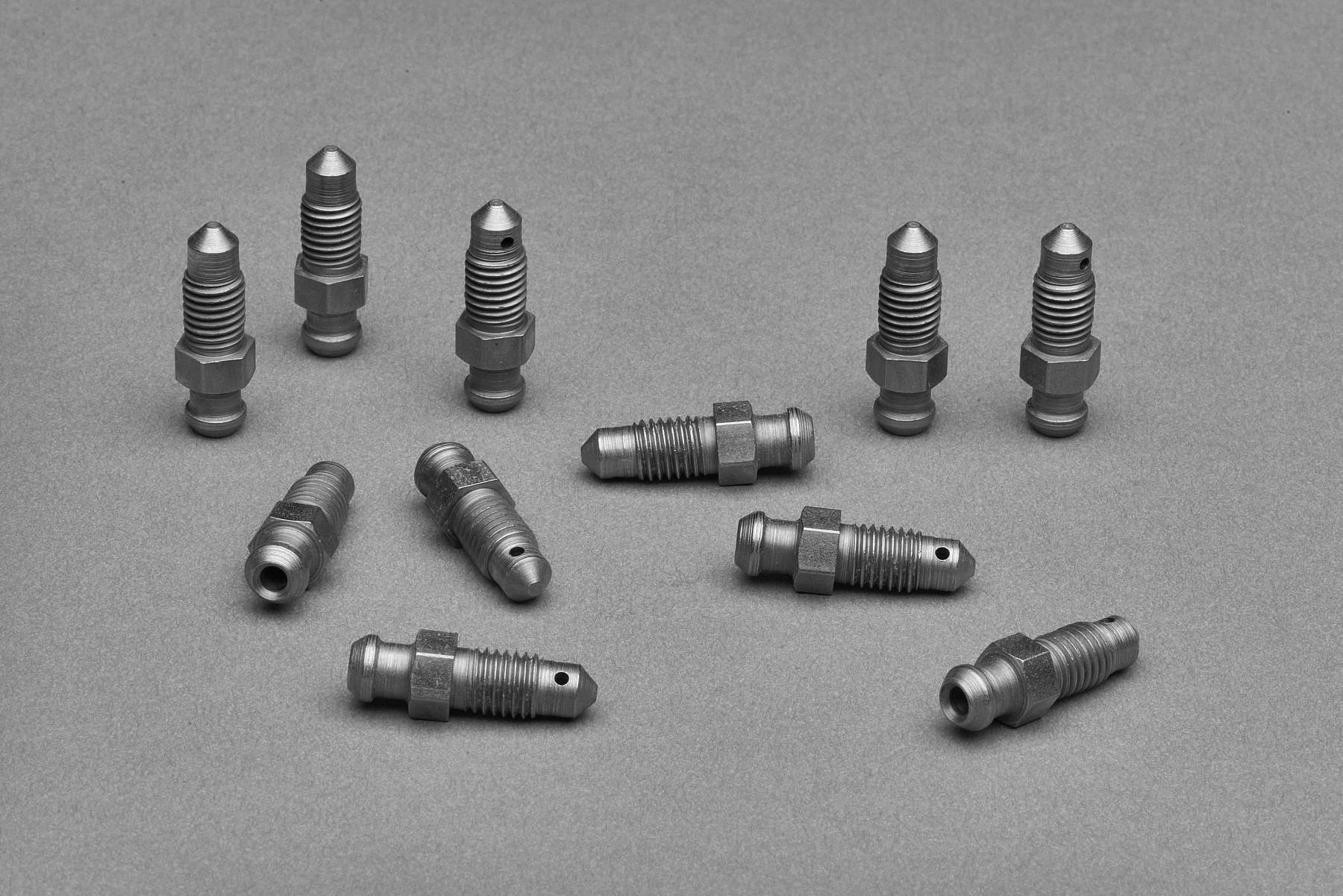

After years of experience with many different customers, in the Italian and international markets, Bleed Screws have become our flagship product.

Bleed screw is a safety part that, after oil change operations in the braking system, allows air to exit from the circuit and ensure the correct braking of the vehicle.

Currently, this component represents around 95% of total production. This product is used on cars, bikes, trucks but also trains, planes, boats, bicycles.

Through the years, productions for shock absorbers, doors and windows, agriculture, constructions and hydraulics have been experienced as well.

Starting from 2006, thanks to a sophisticated centralized software, we are able to monitor the production process: all machines are connected to a server that automatically manages and records quality controls, maintenance, tool changes and all other activities.

Another device supports the production planning indicating in real time the machines load and saturation.

Statistics are carried out on productivity, deliveries and customer satisfaction.

Any downtime is recorded and analysed, as well as any type of ordinary and extraordinary maintenance.

Even raw material, tools and equipment are under control thanks to an inventory data-base.

Some numbers

Tecnova’s production flow is currently organized in three shifts, six days a week, during which trained personnel with different and specific tasks performs machine set-ups, adjustments, quality controls and other highly specialized operations.

Current volumes are around 4 million parts per month (~ 40-45 million per year).

In the next future new investments are planned, both in terms of new machines to increase production and face the high demand, both in terms of final inspection systems to improve even more the finished products quality.

RAW MATERIALS

In addition to the most used AVP steel (11SMnPb37/30), raw materials that we are able to manufacture include R80, Inox, Brass, Steel 8.8.

In compliance with environmental principles, we can manufacture unleaded parts in AVZ (11SMn37) as well. Best practice when machining materials with such different characteristics, we are served by the most famous and reliable cutting tools suppliers, always attentive to new market requirements.

According to customer requirements, we finish our products with outsourced treatments like surface treatments, heat treatments or heat deburring.

We can assure chrome VI-free treatments, with high resistance in salt spray tests, such as iridescent Zinc Nickel, black Zinc Nickel, Zinc plated type IV, white, Geomet, phosphate, Nickel, electrolytic zinc plating etc.

RAW MATERIALS

In addition to the most used AVP steel (11SMnPb37/30), raw materials that we are able to manufacture include R80, Inox, Brass, Steel 8.8.

In compliance with environmental principles, we can manufacture unleaded parts in AVZ (11SMn37) as well. Best practice when machining materials with such different characteristics, we are served by the most famous and reliable cutting tools suppliers, always attentive to new market requirements.

According to customer requirements, we finish our products with outsourced treatments like surface treatments, heat treatments or heat deburring.

We can assure chrome VI-free treatments, with high resistance in salt spray tests, such as iridescent Zinc Nickel, black Zinc Nickel, Zinc plated type IV, white, Geomet, phosphate, Nickel, electrolytic zinc plating etc.

Tecnova Srl

Via del Commercio 18

17038 Villanova d’Albenga (SV)

Italy