Quality

Precision and reliability are not promises — they’re measurable results

Tecnova operates under a quality system certified according to ISO 9001:2015 and IATF 16949:2016, ensuring compliant products, traceable processes, and a safe, efficient working environment.

Quality is embedded in every stage: from the careful planning of a new project to the selection of suppliers and materials, from the launch of a new production batch to product inspections, delivery, and after-sales support.

In-Process Inspections

We use two integrated inspection systems, designed to minimize any margin of error.

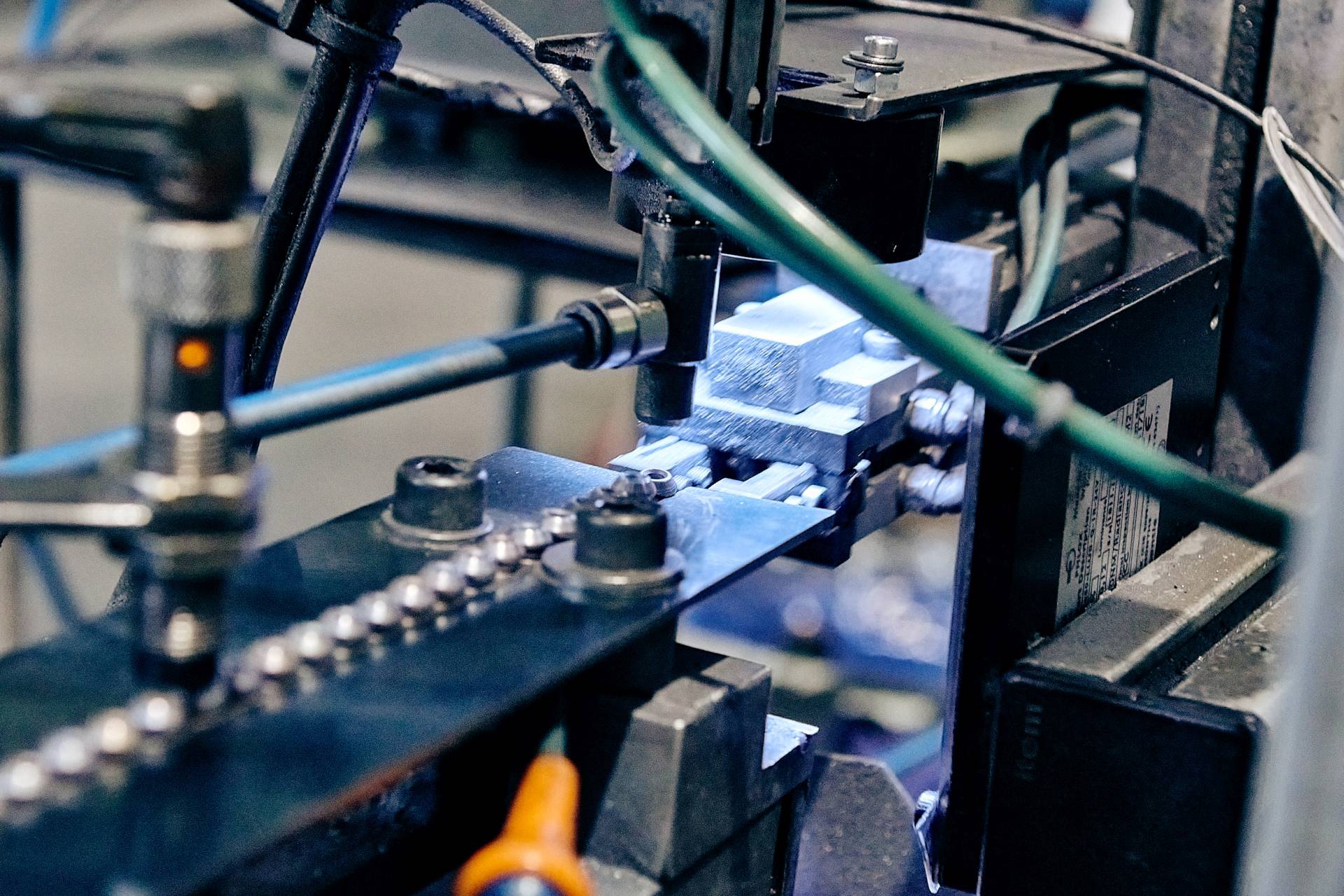

In-process controls: 2 Keyence vision systems operate directly on the shop floor, enabling continuous checks on all active part numbers and real-time statistical analysis.

100% inspections: six dedicated lines for the critical features of bleed screws, equipped with vision systems and pneumatic actuators. The flagship of our production flow.

Methods and Tools

Tecnova applies the main quality tools used in the automotive sector:

APQP, PPAP, MSA, SPC, VDA, along with problem-solving approaches such as 8D, Ishikawa, and 5 Whys.

We constantly monitor PPM, OTD, and key KPIs to ensure performance in line with our customers’ standards.

All measuring instruments are certified for the tests required by our control cycles and are managed using in-house software for identification tracking and calibration monitoring.

Tecnova Srl

Via del Commercio 18

17038 Villanova d'Albenga (SV)

Italy